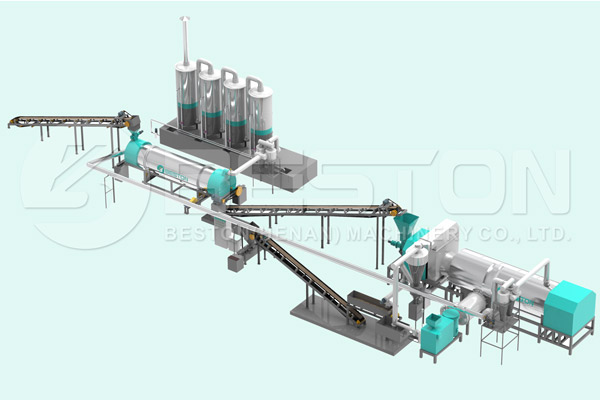

Biomass pyrolysis equipment allows processing plants to convert all types of biomass waste into high-value resources like bio-oil, biochar, biogas, wood vinegar, and tar. Some of the forms of organic waste that can be processed using the latest pyrolysis technology include coconut shells, forest wood, bamboo, various crops, straw, sawdust, risk husks, palm kernels, peanut shells, and olive shells. It is not hard to see why a carbonizing machine is a valuable asset to waste processing plants around the globe.

The Prylosis Process

Prylosis is a thermochemical process. Via the process, all types of carbon-based organic matter are transformed into valuable materials. During the process, organic matter is heated to extremely high temperatures in the absence of oxygen. When organic materials are heated in those conditions, physical, and chemical separation of different molecules occurs. Thermal decomposition then leads to the formation of new products. The temperature of the reactor and the chemical makeup of the raw biowaste materials will determine the proportions of bio-oil, biogas, and biochar that are produced.

Biochar Pyrolysis Equipment Cost

The cost of biochar reactor is influenced by many factors, including the reputation of the manufacturer and their experience in the industry. The best manufacturers have decades of experience in the pyrolysis technology industry, and they produce the most durable and efficient reactors in the marketplace. You can generally obtain a free quote on any of the leading manufacturers’ sites.

You need to keep in mind the requirements of your business when evaluating different biochar pyrolysis plant models from different brands. For instance, what sort of hourly feeding capacity requirements do you have? To calculate that figure, consider how many tons of raw waste materials, you need to process each day and divide that figure by the working time of your business operations. Keep in mind the best biomass pyrolysis reactors have continuous working methods, and they can be kept running 24 hours a day. Some of the smallest models in the market are capable of processing 500kg of biomass waste each hour, whereas some of the larger models can process over three tons of biomass waste each hour. Note that in addition to processing biomass waste, like coconut shells, straw, wood and rice husks, biochar pyrolysis equipment can also process civil sludge, MSW, oil sludge, industrial sludge, and municipal sludge. You can find some useful tips on https://wastetoenergyindonesia.hatenablog.com/.

The Best After-Sales Services

Here are some of the benefits of buying from a supplier that offers great after-sales services:

1. All machinery comes with service support for its lifetime.

2. All machines have a one-year free manufacturer warranty.

3. Quality spare parts are easy to obtain for all machine components.

4. Expedited, tracked shipping services.

5. Engineers on hand to help with assembly, installation, commissioning and operator training.

6. Access to professional tech maintenance advice and machine update services.